Sustainable solutions for the future

WHY TEXTILES FROM TREES?

We’re convinced that the development of Swedish paper-based fabrics to produce interior design, fashion and technical textiles is an intelligent and sustainable way of meeting the needs of tomorrow. Therefore, we create interior design products from the textile materials we have developed. The raw material in our thread and fabric production is manufactured from paper made from Swedish trees, grown with natural precipitation, which reduces all types of environmental impact. Because the paper comes from carefully managed forests, and not from threatened stocks or virgin forest, the manufacturing process doesn’t contribute to deforestation, but instead to lower atmospheric carbon dioxide levels. This means the material isn’t merely environmentally friendly, but also environmentally positive. When the paper is handled correctly, it gives an endless source of carbon-neutral raw material, and the new production technique gives the Swedish forest and textile industry a unique opportunity to replace fossil-based with renewable.

THE TEXTILE INDUSTRY NEEDS NEW RAW MATERIALS

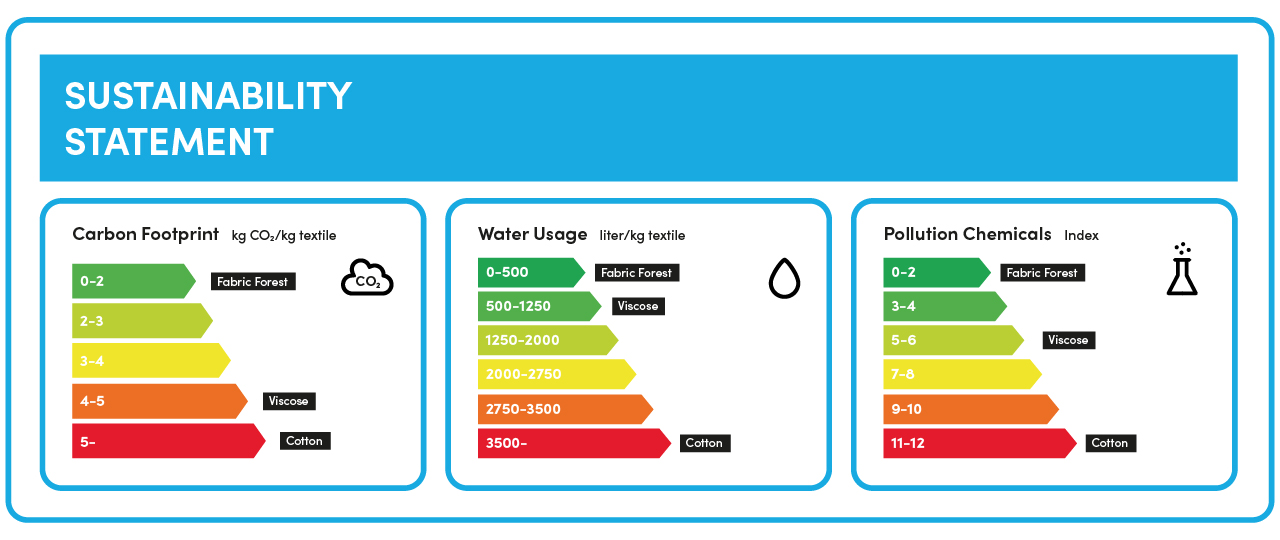

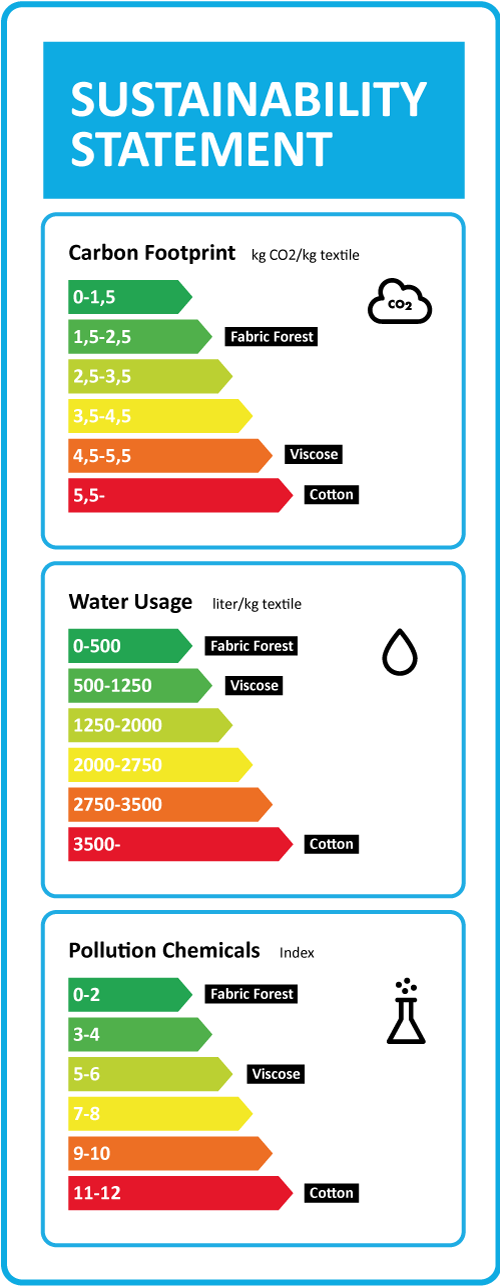

The fashion and textile industry is viewed as one of the worst global polluters. This industry produces 20% of the world’s wastewater, releases vast quantities of greenhouse gases and is one of the biggest consumers of natural resources in the world. The production techniques normally used to produce thread and yarn for textiles include bio-based fibres (such as cotton, viscose and rayon) and synthetic fibres (such as polyester and acrylic fibre). On average, almost 10,000 litres of water are required to produce one kilo of cotton fabric, which makes cotton production responsible for as much as 2.6% of global water consumption. The production of cotton also uses insecticides and pesticides which contaminate and damage both the soil and the people living on it. Other fibres, which are manufactured using synthetic substances, release microplastics when the fabrics are washed. The microplastics then end up in the sea where they jeopardise marine life. Fossil-based, synthetic fibres also have a long half-life, and remain in landfill sites long after they have been used as textiles.

NEW PRODUCTION TECHNIQUES FOR SUSTAINABLE TEXTILE MATERIAL

The world’s textile consumption is increasing dramatically, which has negative effects on the environment. But as the demand for fabrics grows, so too does the need for alternative new raw materials. In recent years, we have seen a development of fabrics manufactured from everything from pineapple and coffee grounds to apple waste and mushrooms. Fabric Forest is proud to be part of this growing global attempt to produce more environmentally friendly fabrics. We are proud to join the ranks of innovators expanding the range of sustainable materials to reduce the environmental impact currently caused by fabric production.

PRODUCING LOCALLY AND THINKING GLOBALLY

As well as the environmental impact caused by the production and processing of traditional fibres, transport also affects the total carbon dioxide impact. During the development of our new fabrics and the production of our interior design products, we’ve stayed close to home. Sweden exports almost 90% of Swedish pulp and paper production. Finding local, sustainable applications for this industry’s renewable and recyclable raw material is of great benefit – both to the Swedish economy and to the entire world. Local manufacturing, together with locally produced and renewable raw materials, makes our interior design products sustainable to a completely different level.